Description

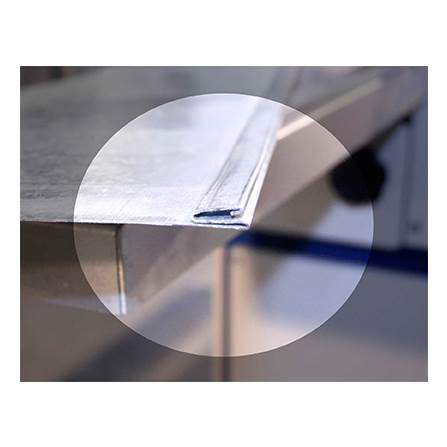

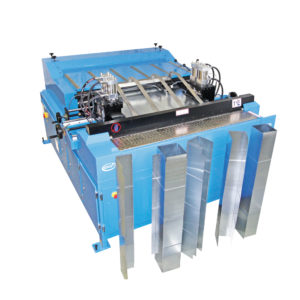

Lock Former machine is employed to join fitting parts by working along the edges of sheet metal. It prepares these two parts by shaping them into the appropriate form prior to their joining. The machine is equipped with two sets of rollers, with the shaping reels on the machine adaptable to various channel combinations. The adjustable roller group allows for pre-bending at the desired angle.

Standard seam types available on the machine:

• Pitsburgh Seam

• Snaplock Seam

• Drive Cleat Seam

• S & Drive S Cleat Seam

• Longitudinal Seam

• Single and double Standing Seam