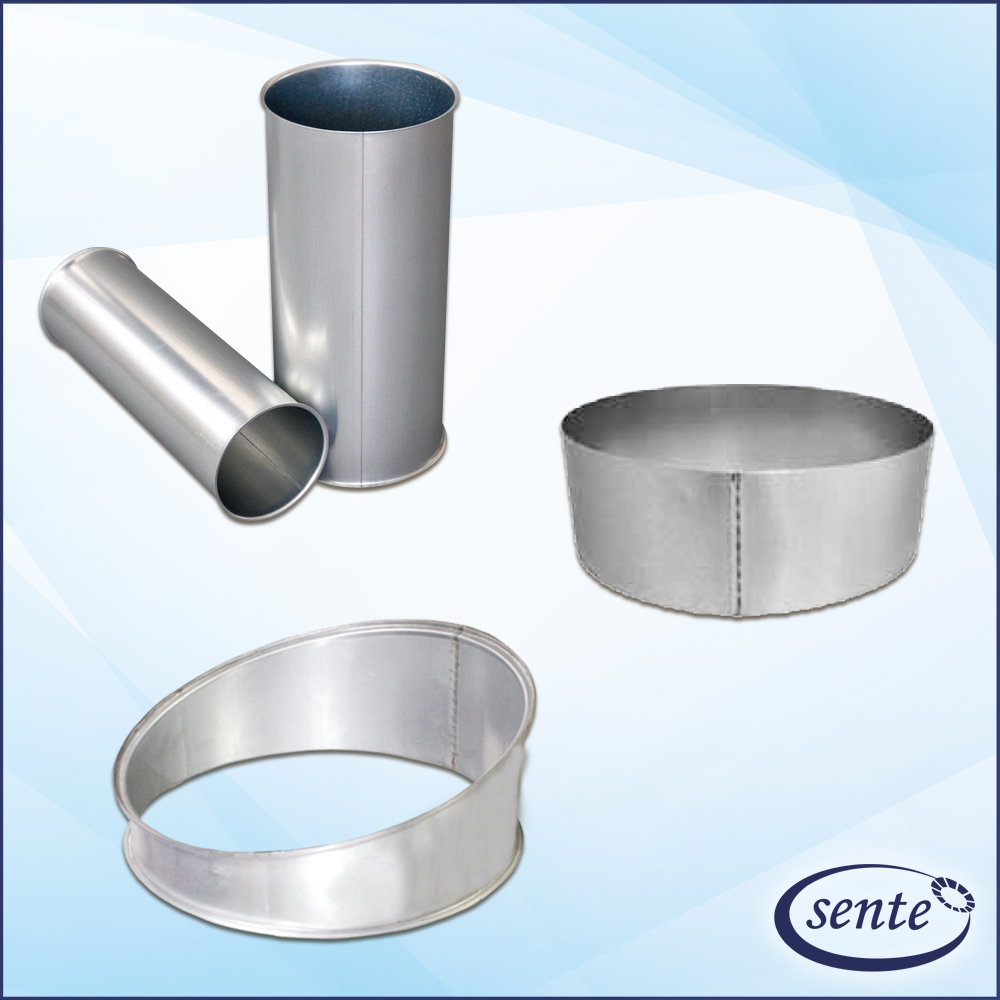

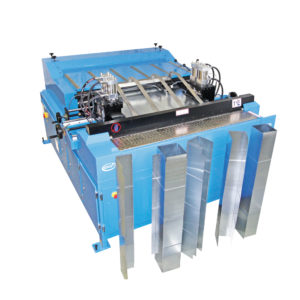

Description

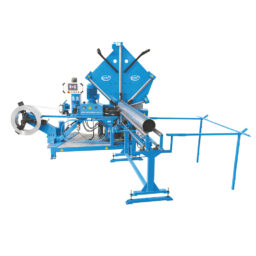

This machine is employed to seamlessly combine round and flat sheets, achieving high-quality results without any burning. Equipped with a user-friendly PLC touch screen, the machine operates fully automatically and is exceptionally easy to use. This automation significantly reduces the risk of operator errors while saving time and labor. The machine o ers both pulsed stitching for galvanized sheets and continuous stitching for stainless steel. When compared to similar machines, it presents several economic advantages:

• Copper wire recycling within the machine conserves resources.

• The machine’s low wire seam allowance results in sheet metal savings.

• Energy effciency is enhanced through the use of a medium-frequency transformer (PATENTED).

• Automatic sheet height detection further streamlines the process, saving valuable time.